| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : QINYI

Model Number : conveyor backstop NF80

Certification : BV,ISO,ISO14001

Place of Origin : China , Cangzhou

MOQ : 10ton

Price : Negotiable

Payment Terms : L/C, D/A, D/P, Western Union

Supply Ability : 5000 Ton/Tons per Month

Delivery Time : 10~15 days

Packaging Details : Steel-strcuture pallet or wooden case

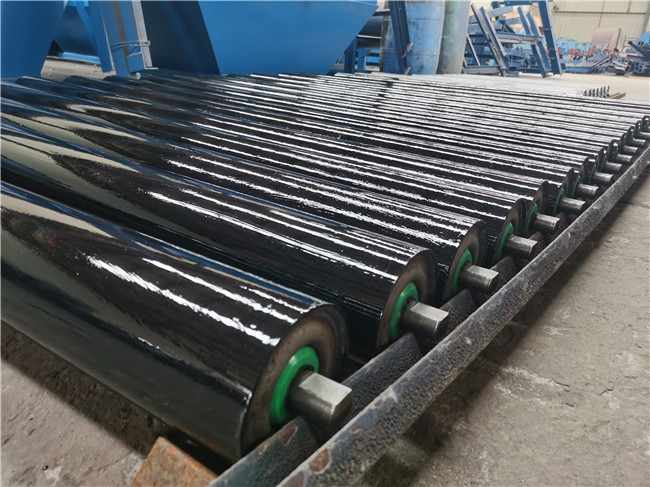

Product name : Driven Belt Conveyor Carrier Roller

Application : Coal Mining, Power plant, port, heat-engine plant

Bearing type : Deep groove ball bearing with C3/C4

Type : Grooved Conveyor Idler

Outside diameter : 30 - 160mm,1 - 320 mm

Bearing Type : Double Sealed Bearing

Tube Material : Steel Z/P, Stainless Steel, Aluminium, PVC

Driven Belt Conveyor Steel Transport Carrier Roller For Port Harbor Roller

Conveyor belt roller & idler is an important part of the belt conveyor, with many kinds and large quantity. It takes up 35% of the total cost of a belt conveyor and bears more than 70% resistance, so the quality of the roller is particularly important.

The role of the roller is to support the conveyor belt and the weight of the material. The operation of the roller must be flexible and reliable. Reducing the friction between the conveyor belt and the roller is crucial to the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor. Although the roller is a smaller part in the belt conveyor, the structure is not complicated, but it is not easy to make high quality rollers.

The criteria for judging the quality of the roller are as follows: the radial runout of the roller, the flexibility of the roller and the axial momentum.

Roller advantages

1. The initial installation of the product is simple;

2. The internal use of thin oil lubrication, the lubrication is more sufficient;

3. The seals adopt international imported brands and cooperate with multiple sealing structures to achieve effective protection;

4. Long service life and low maintenance requirements;

5. The moment arm and the main body are designed separately. When the system needs to be reversed, simply remove the moment arm to achieve

6. Adopting a unique torsion spring design to make each backstop wedge evenly stressed.

7. The core parts are manufactured by special technology to improve the wear resistance of the parts;

8. It is certified by Coal Safety and can be used in explosive environment such as coal mine.

conveyor roller Description

| Characteristics & Features: | |

| High-Density Material | Suitable for High Humidity and High Pollution Environments |

| Anti-Acidic / Anti-Alkaline | Power saving |

| Anti-Static | cost saving |

| Low Noise & Friction | Recyclable |

| good Dynamic Balancing | wide temperature adaptability |

| 50%Lighter than Steel Rollers | Lightweight, easy installation |

| Safe and poison-free and can contact with food and medicine | |

Conveyor Roller Application:

1. Standard: ISO/BS/JIS/DIN/CEMA/Australia

2, High accurate steel material Q235

3, Lift time: more than 30000hours.

3, Production capacity: as usual 50pieces/day.

4. Roller Diameter: 76-219mm.

5. Roller Length: 190mm to 3500mm.

6. Finish: Galvanized/Painting

7. Welding: mixed gas shielded arc welding end.

8. Professional designing and inspection team.

9. Standard: ISO/BS/JIS/DIN/CEMA/Australia

|

|

Driven Belt Port Harbor Iso Heavy Duty Steel Rollers Od 160mm Images |